In Pakistan’s fast-growing construction industry, the demand for safe, efficient, and long-lasting buildings is at an all-time high.

August 18, 2025

In Pakistan’s fast-growing construction industry, the demand for safe, efficient, and long-lasting buildings is at an all-time high. Whether it’s a commercial plaza in Lahore, a hospital in Karachi, or a residential apartment in Islamabad, one thing remains common i.e. the importance of well-installed mechanical, electrical, and plumbing (MEP) systems.

But behind the scenes of every successful MEP installation lies something often overlooked: MEP fixing systems.

In this article, we’ll break down what MEP fixing systems are, why they matter, and how they support modern construction in Pakistan. Let’s dive in.

What Are MEP Fixing Systems?

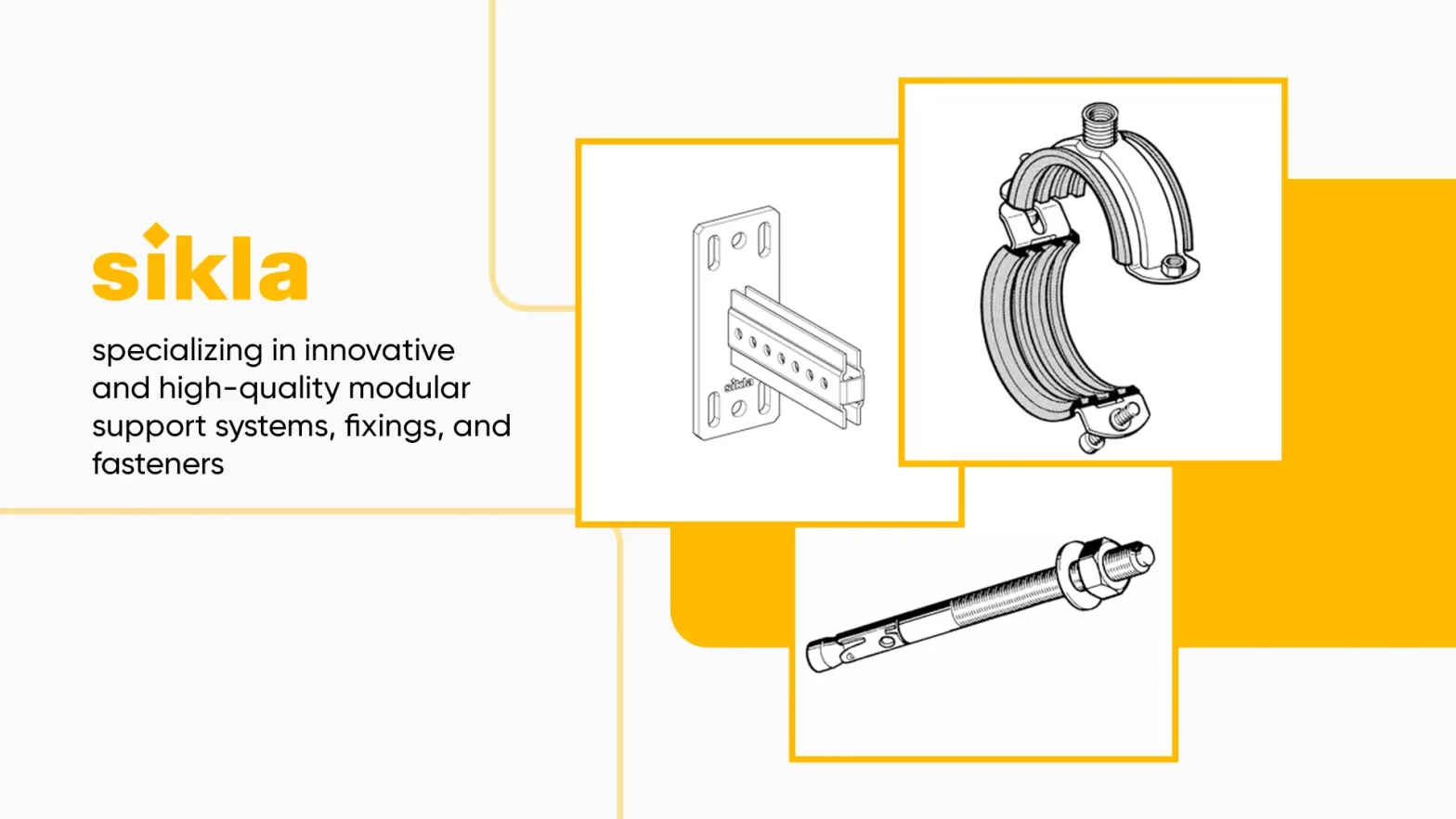

MEP fixing systems refer to the hardware and support structures used to securely install and hold MEP components such as pipes, ducts, cable trays, and HVAC units, in place. These systems ensure that the components are stable, aligned, and protected from physical stress or damage.

These fixings include a wide range of products, such as:

- Pipe clamps and hangers

- Cable tray supports

- Brackets and channels

- Anchor bolts and fasteners

- Modular support systems (like Sikla systems)

- Vibration dampers and seismic restraints

In simpler terms, MEP fixing systems are the backbone of every safe and durable MEP setup.

Why Are MEP Fixing Systems So Important?

Let’s look at some of the key reasons why MEP fixing systems are essential in modern construction:

1. Ensure Structural Stability

In buildings, pipes and ducts often carry heavy loads — water, gas, electricity, or even air pressure. If these are not supported properly, it could lead to sagging, leaks, or even collapse. MEP fixing products ensure that all components remain safely in place, even under stress.

2. Prevent Safety Hazards

Loose cables or unsupported gas pipes can be extremely dangerous. Fixing systems help avoid such risks by keeping everything secure and aligned. This is especially crucial in hospitals, airports, and malls in cities like Karachi and Islamabad.

3. Increase Lifespan of MEP Systems

A well-supported system faces less wear and tear. By using the right fixing products, building owners can reduce the need for frequent repairs or replacements.

4. Support for Seismic & Wind Loads

In areas prone to vibrations or high winds (like parts of northern Pakistan), specialized seismic fixing systems can protect against shaking, shifting, or falling installations.

5. Faster and More Organized Installation

With pre-engineered support systems like modular fixing systems, installers can complete MEP jobs faster and with better precision. This means lower labor costs and faster project delivery.

MEP Fixing Systems in Pakistan’s Construction Industry

In recent years, Pakistan has seen a major boost in infrastructure development. From CPEC-related projects to high-rise buildings and smart housing societies, modern construction now demands higher standards of safety and efficiency.

Growing Demand for Reliable MEP Solutions

With rising awareness and tighter building regulations, more contractors and engineers in Pakistan now demand:

- High-quality fixing hardware

- Certified brands (like Sikla)

- Corrosion-resistant and weather-proof materials

- Customized modular support systems for MEP

This has created a growing market for MEP fixing products dealer in Pakistan, especially in cities like Lahore, Islamabad, Faisalabad, and Multan.

Types of Common MEP Fixing Products

Let’s take a look at some of the essential MEP fixing products used in Pakistani projects:

1. Pipe Clamps & Hangers

Used to support plumbing and HVAC piping, especially on ceilings or walls.

2. Strut Channels & Brackets

These metal channels form the base structure for supporting trays, pipes, and other MEP items.

3. Cable Tray Supports

Keep electrical wiring systems secure and protected.

4. Anchor Bolts and Expansion Fasteners

Secure MEP components into concrete, steel, or masonry surfaces.

5. Modular Support Systems

Ideal for complex MEP arrangements, offering flexibility and easy installation.

6. Seismic Bracing Systems

Used in seismic zones to prevent structural damage to MEP systems during tremors.

Choosing the Right MEP Fixing Systems in Pakistan

When selecting MEP fixing systems for a construction project in Pakistan, here are a few tips:

✔️ Go for Trusted Brands

Suppliers like Ingenious Fixing Solutions offer globally recognized fixing products, such as Sikla Fixing Systems.

✔️ Ensure Corrosion Resistance

Pakistan’s weather — from coastal humidity in Karachi to dry heat in Lahore — can damage low-quality fixings. Use galvanised or stainless-steel fixings for long life.

✔️ Use Modular Systems for Flexibility

Modular fixing systems save time during installation and make maintenance easier later on.

✔️ Prioritize Load Testing & Safety

Always choose fixings that are tested for the expected load conditions of your project.

Why Sikla Fixing Systems Are Popular in Pakistan

Sikla, a leading name in MEP support systems, is known for:

- Pre-engineered modular designs

- Quick installation

- Certified load-bearing capacity

- European manufacturing standards

Available through official distributors like Ingenious Fixing Solutions, Sikla systems are now widely used in high-profile construction projects in Pakistan.

Final Thoughts

MEP fixing systems may not be the most visible part of a building, but they are definitely among the most important. In Pakistan’s evolving construction landscape, using the right fixing solutions is no longer optional but it’s a must.

They ensure safety, efficiency, and long-term value for any project, big or small.

So whether you’re a contractor in Rawalpindi, an engineer in Lahore, or a project manager in Karachi, investing in high-quality MEP fixing systems is one of the smartest decisions you can make.