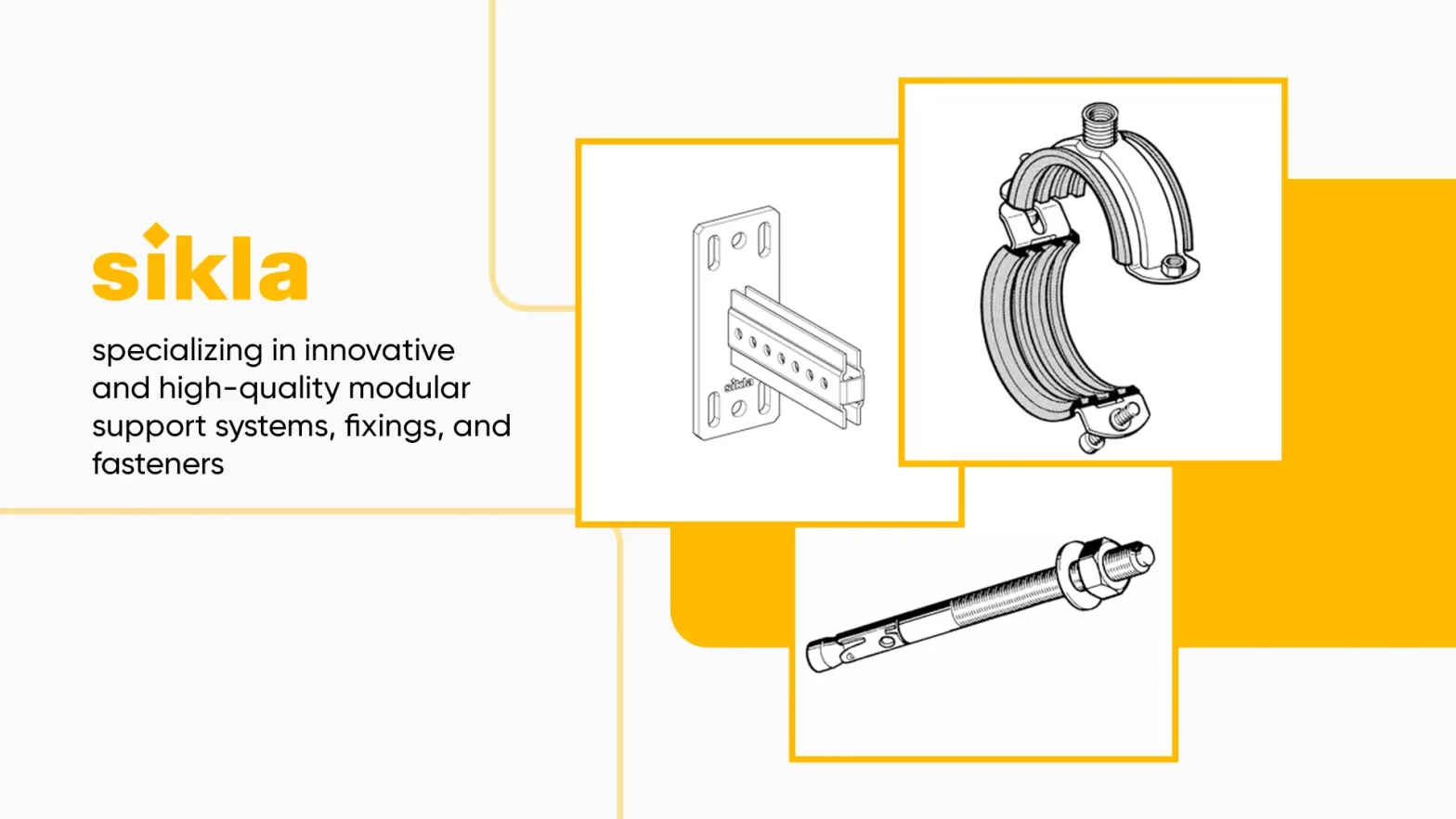

Choosing the right anchoring system is one of the most important decisions in any construction or engineering project. Anchors may look small, but they play a big role. They hold structures in place, support heavy loads, and keep buildings safe over time. Using the wrong anchor can lead to cracks, loose fixtures, equipment failure, or… Continue reading How to Choose the Right Anchoring System for Concrete, Masonry, and Steel

January 19, 2026

Choosing the right anchoring system is one of the most important decisions in any construction or engineering project. Anchors may look small, but they play a big role. They hold structures in place, support heavy loads, and keep buildings safe over time.

Using the wrong anchor can lead to cracks, loose fixtures, equipment failure, or even serious safety risks. That is why understanding how to select the correct anchoring system for concrete, masonry, and steel is essential.

This guide explains everything in simple terms. No complex jargon. Just clear, practical advice that engineers, contractors, and project managers can actually use on site.

What Is an Anchoring System?

An anchoring system is a fixing solution used to connect one material to another. In construction, anchors are commonly used to fix:

- Steel structures

- MEP supports

- Heavy machinery

- Handrails and barriers

- Facades and cladding

- Electrical and mechanical equipment

Anchors transfer loads safely into base materials like concrete, masonry, or steel. The right anchor ensures strength, stability, and long-term performance.

Why Choosing the Right Anchor Matters

Not all anchors work the same way. Each base material behaves differently. Concrete is strong but brittle. Masonry can be weak and hollow. Steel is tough but thin.

Choosing the wrong anchoring system can cause:

- Anchor pull-out

- Cracked concrete

- Weak load capacity

- Corrosion and early failure

- Safety hazards

The right anchor gives you:

- Reliable load performance

- Long service life

- Better safety

- Compliance with standards

- Peace of mind

Key Factors to Consider Before Choosing an Anchoring System

Before selecting any anchor, always evaluate these basic factors.

1. Base Material Type

This is the first and most important step.

Ask yourself:

- Is the anchor going into concrete, masonry, or steel?

- Is the concrete cracked or non-cracked?

Is the masonry solid or hollow?

Each material needs a different anchoring solution.

2. Load Requirements

Understand how much load the anchor must carry.

Consider:

- Static loads (fixed weight)

- Dynamic loads (vibration or movement)

- Shear loads

- Tensile loads

Heavy loads require high-performance anchors with proper testing and approvals.

3. Environmental Conditions

Where will the anchor be used?

- Indoor or outdoor?

- Wet or dry conditions?

- Coastal or industrial environment?

- High temperatures or fire risk?

These conditions affect material choice and coating.

4. Installation Conditions

Ask practical questions:

- Is overhead installation required?

- Is edge distance limited?

- Is fast installation needed?

- Can drilling depth be controlled?

Ease of installation matters on busy job sites.

Choosing Anchors for Concrete

Concrete is the most common base material in construction. It is strong, but it can crack under stress. That is why anchor selection for concrete must be done carefully.

Types of Anchors for Concrete

1. Mechanical Anchors

Mechanical anchors expand inside the concrete to create a strong hold.

Common types include:

- Wedge anchors

- Expansion anchors

- Bolt anchors

Best for:

- Medium to heavy loads

- Structural steel connections

- Handrails and supports

Advantages:

- Immediate load capacity

- Easy installation

- No curing time

Limitations:

- Can create stress in concrete

- Not ideal near edges

2. Chemical Anchors

Chemical anchors use resin to bond the anchor rod into concrete.

Best for:

- Heavy loads

- Cracked concrete

- Close edge distances

- Seismic applications

Advantages:

- High load capacity

- No expansion stress

- Excellent for retrofitting

Limitations:

- Requires curing time

Installation must be precise

When to Use Chemical Anchors in Concrete

Chemical anchoring systems are ideal when:

- Concrete quality is uncertain

- Loads are very high

- Structural safety is critical

- Seismic or fire resistance is required

They are widely used in commercial and industrial projects.

Choosing Anchors for Masonry

Masonry is very different from concrete. It can be solid, hollow, or brittle. Using the wrong anchor in masonry is a common mistake.

Types of Masonry Materials

- Solid brick

- Hollow brick

- Concrete blocks

- Stone

Each type behaves differently under load.

Best Anchors for Masonry

1. Light-Duty Mechanical Anchors

Used for light loads in solid masonry.

Best for:

- Small fixtures

- Electrical boxes

- Light brackets

2. Chemical Anchors with Sleeves

This is the safest option for masonry.

Best for:

- Hollow blocks

- Brick walls

- Medium to heavy loads

Why sleeves matter:

The sleeve controls resin flow and creates a strong bond inside hollow spaces.

Common Mistakes in Masonry Anchoring

Avoid these errors:

- Using concrete anchors in hollow bricks

- Ignoring load limits

- Skipping anchor sleeves

- Over-tightening anchors

These mistakes often lead to anchor failure.

Choosing Anchors for Steel

Steel anchoring is different from concrete and masonry. Here, the anchor connects steel to steel or steel to concrete.

Common Steel Anchoring Methods

1. Through-Bolting

Used when access is available on both sides.

Best for:

- Structural steel

- Platforms and frames

2. Self-Drilling Screws

Drill and fix in one step.

Best for:

- Light steel structures

- Fast installation

3. Chemical Anchors for Steel to Concrete

Often used when fixing steel columns or base plates into concrete.

Best for:

- Heavy steel connections

- Structural applications

Key Considerations for Steel Anchoring

- Steel thickness

- Hole diameter accuracy

- Corrosion protection

- Load direction

Precision is very important when working with steel.

Mechanical vs Chemical Anchors: A Simple Comparison

| Feature | Mechanical Anchors | Chemical Anchors |

| Installation speed | Fast | Moderate |

| Load capacity | Medium to high | Very high |

| Expansion stress | Yes | No |

| Edge distance | Limited | Flexible |

| Cracked concrete | Not ideal | Excellent |

| Seismic use | Limited | Suitable |

Both have their place. The key is knowing when to use each one.

Importance of Approved and Certified Anchors

Always choose anchors that meet international standards.

Look for:

- ETA approvals

- Tested load values

- Fire resistance ratings

- Seismic certifications

Certified anchoring systems provide reliability and long-term safety.

Installation Quality Matters More Than the Anchor Itself

Even the best anchor will fail if installed incorrectly.

Follow these basic rules:

- Drill correct hole size

- Clean the hole properly

- Use correct torque

- Respect curing time

- Follow manufacturer guidelines

Training and supervision make a big difference.

Common Questions About Anchoring Systems

Can one anchor work for all materials?

No. Each base material needs a specific anchoring solution.

Are chemical anchors always better?

Not always. Mechanical anchors are faster and cost-effective for many applications.

Can anchors be reused?

No. Anchors are designed for one-time use only.

Is corrosion protection important?

Yes. Especially in outdoor and industrial environments.

Final Thoughts

Choosing the right anchoring system for concrete, masonry, and steel is not complicated when you understand the basics. The key is to look at the base material, load requirements, environment, and installation conditions.

Anchors may be small, but their impact is huge. The right choice improves safety, reduces risk, and ensures long-term performance.

When in doubt, always choose tested, approved anchoring systems such as MKT Anchoring and fastening systems officially distributed in Pakistan by Ingenious Fixing Solutions and follow proper installation practices. It saves time, money, and prevents costly failures.